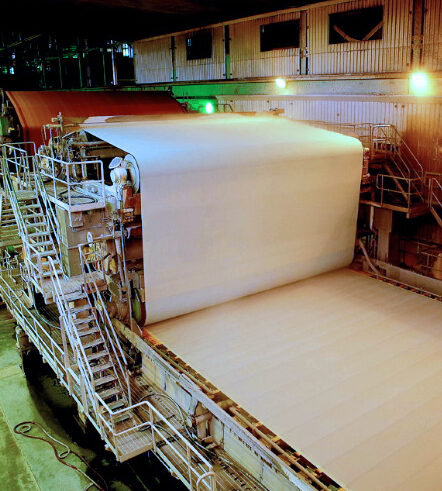

Bob gathering pulp samples for wet end chemistry analysis.

Bob gathering pulp samples for wet end chemistry analysis.

Bob Howard founded Starch Performance Services in 2010 to fill a need for periodic expert analysis, trial support, grade development, and education on best practices for the optimal use of wet end, size press, and coating starches in the manufacture of paper products.

Bob has over thirty-five years of technical sales experience, having worked for A.E. Staley Manufacturing Company, Penford Products Company, and Western Polymer Corporation.

Bob is recognized as an expert in wet end chemistry analysis, a technical specialist for paper mills producing coated and uncoated printing papers, bleached packaging board, newsprint, liner, and medium. He is an excellent advisor and problem solver in the use of starch and papermaking issues, generally. Bob has worked throughout the United States and western Canada, South America, and Europe.

In August, 2012, Starch Performance Services NL was registered in The Netherlands to facilitate opportunities throughout the European Union.

Starch Performance Services also has an affiliated office in Quito, Ecuador. Please see the Contact Us page for details.

In 2019 Jon Saatvedt began working with Starch Performance Services. Jon brings many years of experience from paper machine and stock prep operations as well as product development. Jon is a welcome and complementary addition to Starch Performance Services’ capabilities.

SERVICES

There is more to performance and quality on a paper machine than just filling the silo with a commodity starch. Achieve optimum machine runnability and paper quality by sourcing superior performance starch products from a supplier with the commitment and expertise to support your efforts.

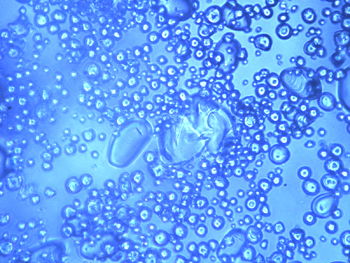

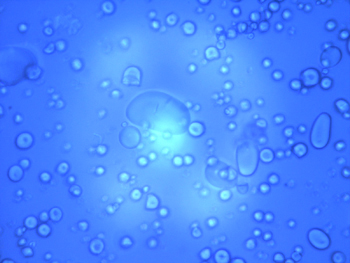

Large Type II Amylose crystals

Paper machines often encounter unanticipated challenges to quality, runnability or customer complaints that exceed the scope of normal machine operations. Much of the in-house expertise for starch and chemistry issues that once existed has been lost through cut-backs and attrition.

Below are a few scenarios in which Starch Performance Services can help:

Consistency matters!

- Choose the correct starch type and charge density;

- Optimize cooking temperature, pasting and dispersion of cationic wet end starch;

- Identify the optimum dose and addition point selection.

- Manage surface starch solids and viscosity to effect pick-up and penetration to optimize surface strength or internal bond.

- Avoid surface starch retrogradation or amylose fractionation that can significantly impact uniform application, sheet performance, runnability, and cost.

SPS support services include:

- Cationic wet end starch selection and optimization.

- Starch preparation, paste quality, storage, transfer, and addition-point evaluation. Cooker audits.

- Paper machine wet end chemistry evaluations (cationic demand, zeta potential, drainage, retention, and strength).

- Size press starch selection, evaluation and recommendations.

- Coating starch recommendations and formulation assistance.

- Problem solving – Machine efficiency, runnability, breaks, or paper quality issues.

- Wet end analysis – Web breaks, ash retention, machine speed, deposits and sheet deficiencies are issues that often require specialized analysis and measurement to achieve a successful resolution.

- Starch trials and starch maintenance services.

- Grade development assistance– Product recommendations, lab work, and trial support.

All of these services are available on an as-needed, contract basis or as an integral component of a continuous supply agreement. Starch Performance Services can fill the gap and maximize the value from the starch used in your paper manufacturing process.

Bob gathering pulp samples for wet end chemistry analysis.

Bob gathering pulp samples for wet end chemistry analysis.

Bob Howard founded Starch Performance Services in 2010 to fill a need for periodic expert analysis, trial support, grade development, and education on best practices for the optimal use of wet end, size press, and coating starches in the manufacture of paper products.

Bob has over thirty-five years of technical sales experience, having worked for A.E. Staley Manufacturing Company, Penford Products Company, and Western Polymer Corporation.

Bob is recognized as an expert in wet end chemistry analysis, a technical specialist for paper mills producing coated and uncoated printing papers, bleached packaging board, newsprint, liner, and medium. He is an excellent advisor and problem solver in the use of starch and papermaking issues, generally. Bob has worked throughout the United States and western Canada, South America, and Europe.

In August, 2012, Starch Performance Services NL was registered in The Netherlands to facilitate opportunities throughout the European Union.

Starch Performance Services also has an affiliated office in Quito, Ecuador. Please see the Contact Us page for details.

In 2019 Jon Saatvedt began working with Starch Performance Services. Jon brings many years of experience from paper machine and stock prep operations as well as product development. Jon is a welcome and complementary addition to Starch Performance Services’ capabilities.